A Collaborative Approach to Success

We take a consultative approach when working with customers to ensure you receive the best overall solution for your specific situation.

Let's Build Your Future Together

Other designs on the market are typically sold “as-is”, and if something else is needed, you’re on your own.

With Heat Recovery Innovations, we listen to your requests and provide a robust flexibility of design that isn’t readily available elsewhere. You get a completely customizable product that is smaller, more efficient, and primed to meet a wide range of heat transfer and system requirements.

Concept

Define Requirements

and Expectations

Collaborate to clearly understand your challenges and goals.

Prototype

Build a Prototype

for Testing

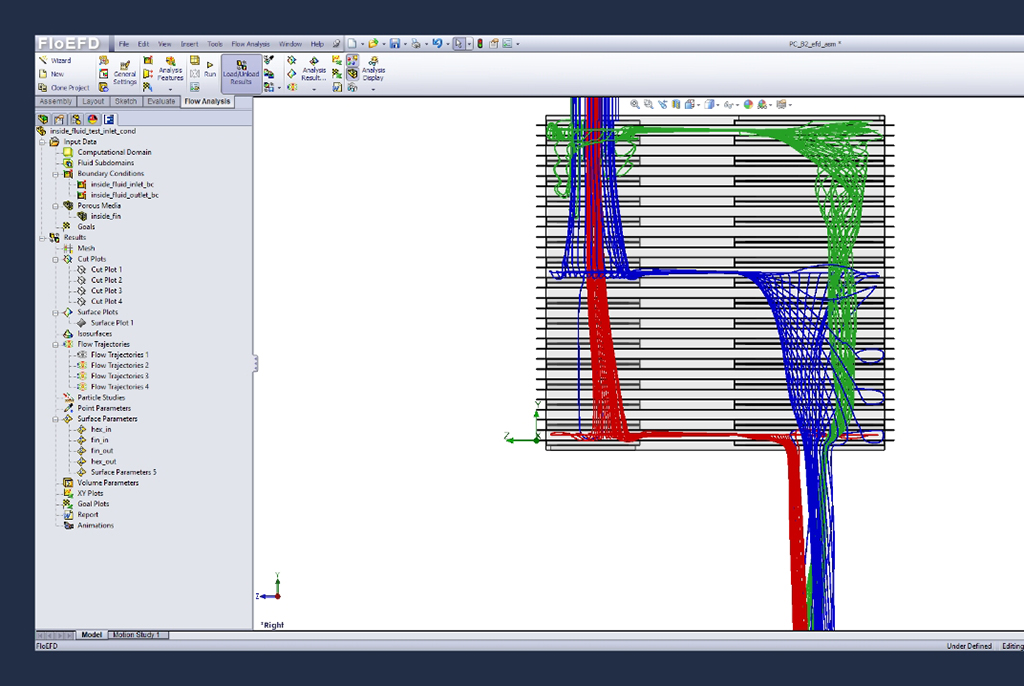

New designs are modeled and analyzed with CFD to confirm the concept meets the objectives before the first article is produced.

Optimization

Flexibility in the

Design Process

Refine designs as data is collected to optimize design for performance, cost, and size.

Production

Low and High-

Volume Orders

Provide support through all project stages, from initial prototypes to high volume production.

Maximize Efficiency and Meet Cost Reduction Targets

Bring us your project. We will work with you to develop the precise solution for your heat recovery needs. Reach out today.

Tackling complex challenges with modern solutions.

Companies are pressured to show how they are responding to the energy transition. Whether faced with state-wide regulations or global demand, creating and executing a path forward that meets the needs of both today and tomorrow is a significant challenge.

That’s where we come IN.

Heat Recovery Innovations works with our customers to understand exactly what is required for success. At the core of every application we sell is a waste heat recovery process that is truly game-changing, reducing operating costs and carbon emissions.

So, whether your goal is to increase fuel economy to reduce operating costs or to enable hydrogen and/or carbon capture, HRI creates the carbon-free solutions that will dominate our future.

Scaling to meet your growing demands

From prototype to production, if you’re building an all-new system, we can produce smaller-scale prototypes to support your development process. We mutually learn from creating and testing these prototypes, honing the solution along the way. When it is time to commercialize the project, HRI will be your partner for high volume production.

Designing best-in-class products with integrity

With our proprietary, in-house developed heat exchanger sizing tools and prototyping ability, we can create multiple designs, quickly run tests, and make changes to achieve the performance you require. This best practice also saves time and money when tailoring our technology into your custom solution.

Our Manufacturing Facility

45,800 sq. ft. manufacturing facility with expansion capability

20+ year developed supply chain designed to scale with our growth

Instrumented test cell (375kW) with thermal, cycle, flow, and pressure test capability

Proprietary braze application with custom, innovative braze fixture design

Robotic plasma welding; spot, seam, plasma, TIG, and MIG welding