Home / Technology + Solutions / Fin Shell Heat Exchanger

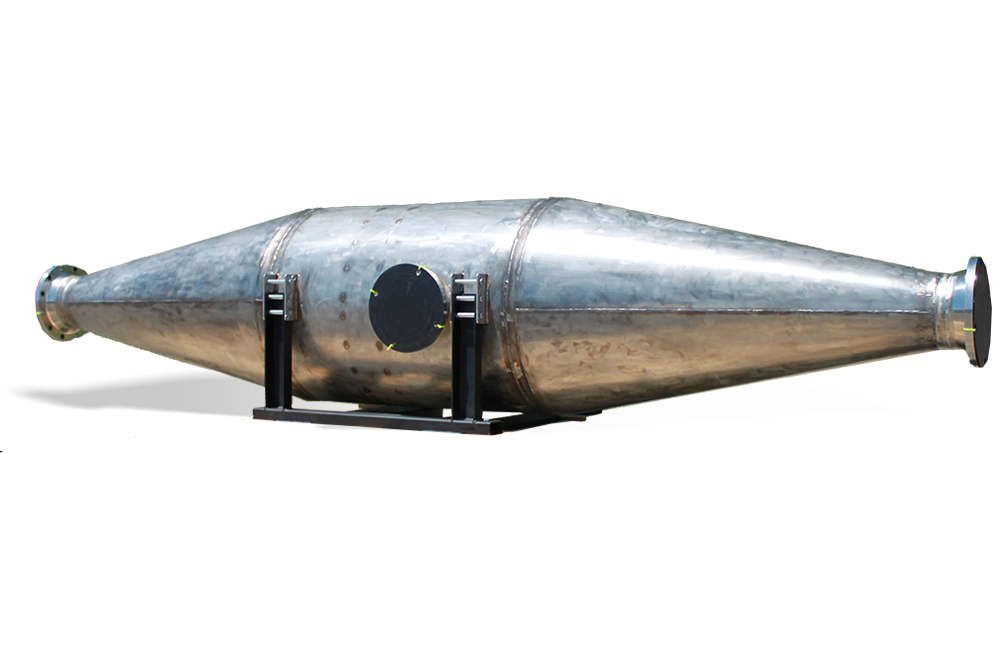

Fin Shell

Heat Exchanger

Leverage Increased Surface Innovation

Patented design yields less energy consumption

The compact packaging of Heat Recovery Innovation’s Fin Shell Heat Exchanger delivers maximum heat transfer in minimum space. Our team carefully designs the exchanger with the exact shaped fin necessary to yield the results you’re looking for. These fins separate the plates to create flow channels that improve the internal and external tube heat transfer rates and provide superior cooling of large volumes at low pressure drops.

HRI’s Fin Shell heat exchanger is ideal for customers who require a reliable, high-quality heat exchanger that is low maintenance, long-lasting, and more compact than other available designs. Even with an enlarged surface on the shell side, customers achieve increased heat transfer rates across the board with this highly efficient and space-saving solution.

Quick Specs

| Design Pressure | Design Temperature | Applications |

|---|---|---|

| Up to 100 psig | 7 barg | Up to 1000ºF+ | 538ºC+ | Gas/Gas Heat Recovery |

| Advantages | Markets | |

|

| |

| Design Pressure |

|---|

| Up to 100 psig | 7 barg |

| Design Temperature |

| Up to 1000ºF+ | 538ºC+ |

| Applications |

| Gas/Gas Heat Recovery |

| Advantages |

|

| Markets |

|